Centerboard trunk

Centerboard trunk surface has to be sturdy and slippery. So, it was covered with glassfibre and graphite mixed into epoxy. I also learned that the plywood should not be brought from cool temperature to warm prior to applying epoxy or bubbles result. The graphite coated surface reminded me of licorice sauce…

Width of the centerboard trunk should be centerboard thickness plus 3.1-4.8 mm on the both sides. In other words, in case of Merisirri, the range can be determined with the following formulas.

Width of the centerboard hole is 61 mm, so the case width will be close to the lower limit. Glassing of the panels made them slightly ticker than 9 mm. The centerboard case stocks were be made 43 mm wide.

Actually before the centerboard trunk I glued bulkheads 4-7 and seat longitudinals together.

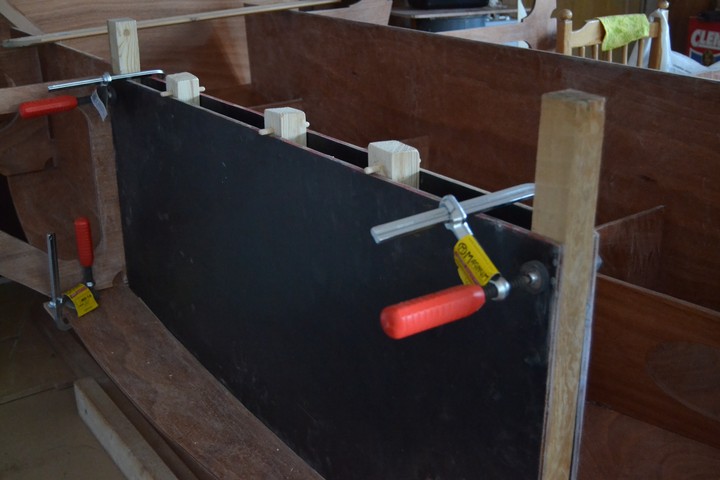

Clamping the starboard doubler was trickier as you had to avoid bending the centerboard panel. Notice that the panel was accidentially graphite coated on the both sides.

| Next: | Bulkheads 4-7 and seat longitudinals |

| See also: | Building Merisirri |